Custom Die Casting Service

Die casting process offers well-detailed, durable, and high quality die cast metal parts. With the use of specialized molds and techniques. This method produces components with dimensional tolerances.

At DEK, we offer high-quality die casting services while taking note of your unique project requirements. Our services are relatively cheaper than industry standard, thus allowing you to get a durable component at a relatively fair rate. Whether you require a rapid prototype or mass production, we can provide you with flexible solutions.

introduction

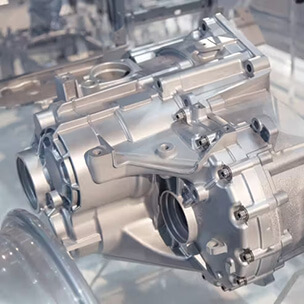

Precision Die Casting for Custom Components

DEK offers highly precise, durable die casting services for clients within many industries. Our manufacturing process isn’t just fast but is also efficient and reliable.

With the use of advanced technological machines and tools, teams of experts, and a variety of materials, we deliver the best die casting services across several industries. When fast and effective delivery matters to you, you can count on us. We have streamlined logistics solutions for that. Whether you want just a few components or mass production, we're here to serve– no minimum order quantity.

- Tolerance level of +/-0.01mm

- Fast turnaround time of 4-7 days

- No minimum order quantity

- Ability to handle complex geometries

- ISO 9001:2015 certified

- Variety of material available

Materials for Die Casting

Metals

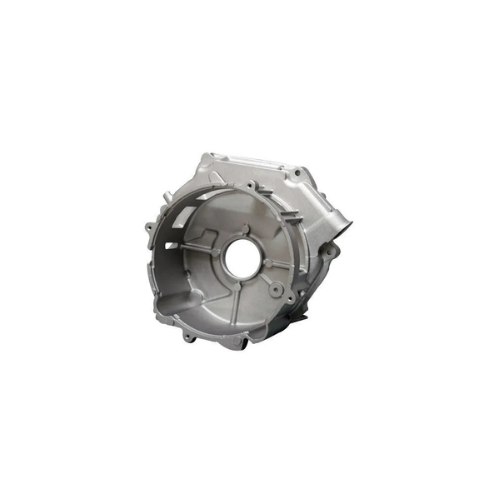

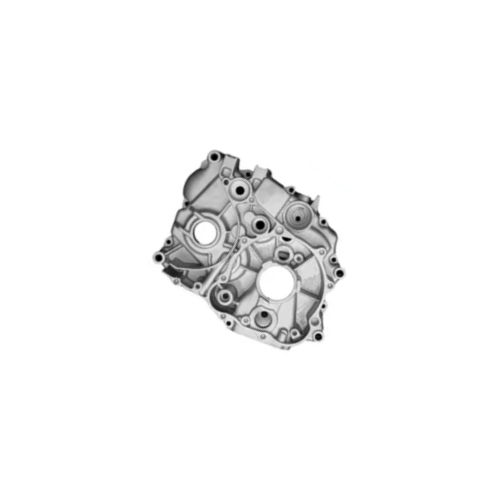

Aluminum

Aluminum is a lightweight, corrosion-resistant metal known for its excellent strength-to-weight ratio and good thermal conductivity. Suitable for die casting due to its quick solidification, making it ideal for producing intricate parts with thin walls.

At DEK, we use aluminum to create durable parts for the automotive, aerospace, and electronics industries. You’ll find us producing aerospace engine enclosures, heat sinks, and transmission covers.

Alloy

Aluminum 2024, 5052, 5083, 6060, 6061

Brass

Brass is an alloy of copper and zinc that offers a rich combination of strength, corrosion resistance, and an attractive golden appearance. It’s commonly used in applications where both performance and aesthetics are required.

Our high-quality die casting service allows us to deliver precision components in the plumbing, marine, and decorative hardware industries. We utilise brass in producing valve bodies, marine propeller hubs, and luxury faucet handles.

Alloy

Brass 260, C360, Cz121

Bronze

Bronze is a strong, corrosion-resistant alloy composed mainly of copper and tin. It offers excellent wear resistance and performs well in applications where there's exposure to friction.

At DEK, we use bronze to produce high-quality components for marine, industrial, and power systems. You benefit from our precise tooling, excellent dimensional control, and refined surface finishes. Our die casting methods ensure your parts maintain structural integrity, minimal porosity, and consistency across every production run.

Alloy

Bronze 544, 841, 932, 954

Copper

Copper is a highly conductive, durable metal known for its superior thermal and electrical properties. It also resists corrosion and maintains strength under extreme conditions.

At DEK, we leverage copper in die casting to support industries like electronics, automotive, and energy. You can rely on us for consistently accurate parts with excellent thermal transfer and conductivity. Our process ensures tight tolerances, smooth finishes, and the durability needed for critical, high-load applications.

Alloy

Copper C101, C110

Lead

Lead is a dense, malleable metal with excellent shielding and vibration-dampening capabilities. While its use is limited to specialized applications, it remains essential in sectors that require controlled radiation or sound insulation.

At DEK, we use lead to serve clients in the medical and automotive sectors. Our die casting process produces uniform, high-density parts with reliable sealing and accurate dimensions. You benefit from our advanced finishing techniques, quality assurance, and the ability to deliver precision even in low-volume.

Alloy

PbSb10, PbSn30, PbAg1.5

Magnesium

Magnesium is a light structural metal, offering an outstanding strength-to-weight ratio. It provides excellent thermal performance and shock resistance, making it ideal for lightweight yet high-strength applications.

At DEK, we cast magnesium parts for industries such as aerospace, electronics, and transportation. Our die casting technology delivers fine detailing, consistent dimensional accuracy, and excellent repeatability. You’ll receive components with smooth surfaces, reduced weight, and minimal post-processing.

Alloy

AZ31B, AZ61B, and AZ91D

Zinc

Zinc is one of the most popular die casting metals due to its excellent fluidity, strength, and ability to cast into intricate shapes. It also offers good wear resistance and dimensional stability.

We utilize zinc in providing highly precise die casting services for automotive, electronics, and consumer industries. We create door lock housings, pressure-tight casings in security hardware, and appliance knobs. Our zinc casting solutions offer tight tolerances, superb surface smoothness, and reduced machining needs.

Alloy

Zamak 3

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Our Advantages

2300+ Engineers Love Work With Us

High Precision

Our die casting process is engineered for precision. With advanced equipment and expert technicians, we achieve tolerances as tight as ±0.01mm. This means the parts you receive are accurate, consistent, and ready for high-performance applications.

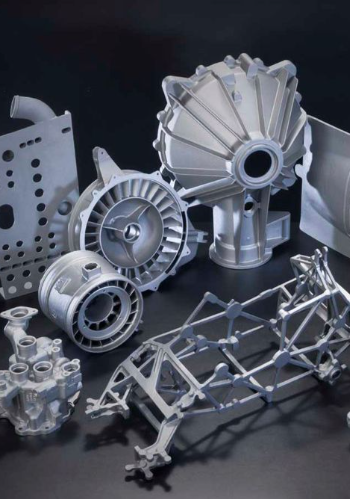

Complex Geometries

DEK's high-pressure die casting allows us to create intricate parts with thin walls, undercuts, and fine details that other methods can’t handle. You don’t have to simplify your design as we have the tools and expertise to produce exactly what you envisioned.

Certified Quality

Our facilities meet international standards such as ISO 9001:2015, so you can trust that every die cast part is made with strict quality control. You get reliable, consistent quality every time, with traceability and documentation for complete transparency.

No MOQ

At DEK, we adapt to your production volume and timeline, making it easier and more cost-effective for startups, custom projects, or trial runs. You get flexibility, fast turnaround, and the same high level of quality, regardless of quantity.

Material Versatility

You get access to a full range of die casting metals at DEK. You’re not stuck with limited options as we help you choose the best-fit metal based on performance, cost, and application, and ensure it’s cast to perfection.

Cost Effectiveness

DEK helps you reduce costs without sacrificing quality. Our efficient tooling, rapid cycle times, and minimal post-processing needs make die casting a highly economical choice, especially for medium to high volumes.

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

Die Casting Buying FAQs

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayUnderstanding Die Casting

What is Die Casting?

Die casting is a manufacturing process where molten metal is injected into a mold cavity under high pressure to create precise, repeatable metal parts. You typically use this process when you want to produce a large number of parts that are strong, dimensionally accurate, and have smooth surface finishes.

The molds, also known as dies, are made from hardened steel and can be reused thousands of times, which makes the process very efficient for high- volume production. You can choose from several metals, including aluminum, zinc, and magnesium, depending on the specific performance and weight needs of your part. Die casting is especially useful when you’re working on components for industries like automotive, electronics, appliances, and industrial equipment that require strength, durability, and precision.

What are the advantages of Die Casting?

Die casting gives you the ability to produce high-strength, complex metal parts with great surface finishes, while keeping production efficient and cost-effective for larger quantities. It’s one of the best ways to manufacture parts that need both performance and precision.

Here are some of the main benefits you’ll enjoy:

● Excellent dimensional accuracy

● Ideal for large orders

● Smooth surface finishing

● Complex shapes and geometries

● High material utilization

● Thin-walled components

When do you need Die Casting?

You need die casting when you want to produce a high volume of metal parts that are consistent in quality, complex in design, and durable in performance. This process is especially useful when your project demands tight tolerances, a smooth finish, and the ability to repeat the same geometry thousands of times.

If you're working in industries like automotive, aerospace, consumer electronics, or industrial machinery, die casting can save you time and money. It’s also the right choice when you’re looking to reduce the number of separate components by combining features into a single, integrated part. If your part needs to be lightweight yet strong, such as with aluminum or magnesium, die casting is likely the ideal method to consider.