This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- Home

- Materials

- CNC Machining Metal

- Aluminum

- Aluminum MIC6

Aluminum MIC6

Material Type

Metal

Material Name

Aluminum MIC6

Process Compatibility

CNC Milling, CNC Turning

introduction

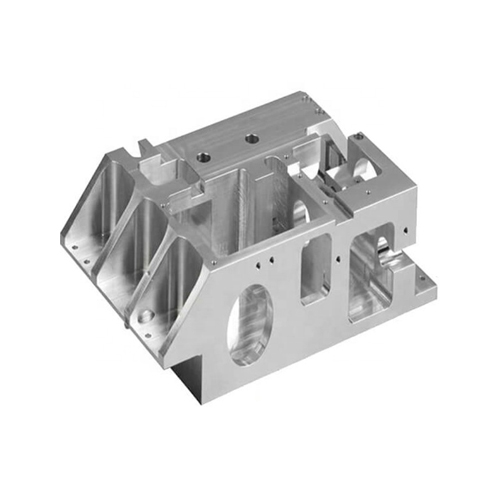

Aluminum MIC6 in CNC Machining

MIC-6 is a cast aluminum plate made from a mix of metals. It offers high accuracy and easy machinability. The casting process gives it stress-relieving properties

MIC6 is highly used for precision CNC machining due to its outstanding flatness and stability. It possesses a fine-grain structure that enhances mechanical properties. It is lightweight, smooth, and free from tension, contaminants, and porosity. With excellent thermal conductivity, MIC6 effectively dissipates heat during machining, reducing the risk of thermal distortion. This material's machinability makes cutting, milling, and drilling easy. Manufactured with tight dimensional tolerances, MIC6 guarantees consistency and precision in the final product, remaining stable under varying temperatures.

MIC6 has a smooth surface finish, improving the machined parts' surface quality. Anodizing capability allows surface hardness, corrosion resistance, and wear resistance enhancements. Despite being pricier than standard aluminum alloys, MIC6's distinct properties and advantages in precision applications justify its cost. Standard sizes are readily available, facilitating convenience in CNC machining projects.

Properties

Properties Table of Aluminum MIC6

| MECHANICAL PROPERTIES | |

|---|---|

| Ultimate Tensile Strength | 160-170 MPa |

| Yield Strength | 70-130 MPa |

| Young's Modulus(Elasticity) | 71 GPa |

| Elongation at Break | 3-7 % |

| Physical Properties | |

| Corrosion Resistance | Good |

| Magnetism | Non-magnetic |

| Weldability | Good |

| Thermal Properties | |

| Maximum Service Temperature | 427°C |

| Thermal Expansion Coefficient | 23.6-24.5 x 10^-6/°C |

| Thermal Conductivity | 142 W/(m·°C) |

| Electrical Properties | |

| Electrical Resistivity | 4.79 μΩ*cm |

TECHNOLOGY OVERVIEW

Basic Knowledge of Aluminum MIC6

What is Aluminum MIC6?

MIC6 is a precision cast aluminum tooling plate known for its superior flatness, stability, and machinability. The fine-grained structure of MIC6 ensures exceptional dimensional stability. Its ability to undergo anodizing further enhances its corrosion resistance and aesthetics.

With excellent thermal conductivity, MIC6 efficiently dissipates heat. The plate's reliability and ease of machining contribute to its popularity in producing precise components and tooling.

Advantages of Aluminum MIC6

- Excellent flatness and stability

- Ideal for precision machining applications

- Low internal stress and tight thickness tolerance

- Uniform hardness for enhanced machining performance

- Cast plate structure reduces the need for extensive post-machining processes

Applications of Aluminum MIC6

- Machined fixtures and tooling plates for aircraft parts

- High-precision chassis and enclosures

- Inspection gauges and jigs

- Precision components in medical imaging machines

- Tooling used in the fabrication of lenses and other optical elements.

FAQ

Machining Aluminum MIC6 Buying FAQ

Other Materials

Aluminum 7075

Aluminum 7075 is a strong and lightweight alloy often chosen because of its high strength-to-weight ratio. It is widely used in CNC machining

Aluminum 6063

Aluminum 6063 is mainly composed of aluminum, magnesium, and silicon. Its excellent machinability makes it commonly used in CNC processes.

Aluminum 6061

Aluminum 6061 (CNC) is the most popular aluminum alloy. It has good strength-to-weight ratio, excellent machinability and natural corrosion resistance.

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote Today